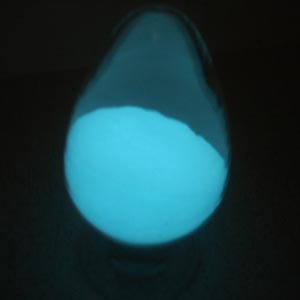

Photoluminescent pigment

Glowing color: Yellow green, Blue green, Sky blue, Purple, other colored glow powder

Luminance grade: Super grade, Normal grade, Economic grade

Particle size: 15-20um, 20-25um, 25-40um,70-80um and Customized according to customer requirements

Origin: China

Other key words: Glow in dark powder manufacturer, Luminous powder, long afterglow phosphor, strontium aluminate phosphor, phosphorescent pigment

- Description

- Inquiry

Description

Introduction:

Photoluminescent pigments is made mainly from the rare earth element and aluminate material. The chemical formula is SrMgAl4O8:Eu2+Dy3+. After absorbing the natural light or lamplight about 15 minutes, the powder can shed continual light with colour of yellow green , blue green or others for longtime. The powder is a non-radioactive, non-toxic and Green-Protection products. It is not belong to flammable , oxidizer , corrosives and other dangerous goods. It is safety for all kinds of transport type. It can be used in many transparent or translucent media, such as plastic, paint, glaze, ink, glass and ceramic etc to produce luminous products. With the good indicating and beautifying effect in darkness, the powder can be widely used in emergency signs, passway signs, switches, enamel nameplate, road signs, toys, handicraft, clock, textile, military and camp instruments etc..

Characteristics

The photoluminescent pigment will be dissolved in water and decomposed in acid liquid somewhat, so it can not be used in water-solubility and acidity solution. For these purpose, we will produce the waterproof pigments.

Fast light absorbing, high glowing effect and long afterglow time.

With better stable characteristic of physics and chemistry, strong acclimatization and long service life.

It is a new type of environmentally friendly photoluminescent pigment with the characteristics of non-toxicity, non-radioactivity, non-flammability and non-explosibility.

Small particle diameter, granularity distributes equally, easy to produce during process.

The smaller the particle size,the lower the luminance is.

Application fields

Suitable for various kinds of transparent or half transparent medium, such as paint, screen printing, plastic, glass, coating, ink, enamel, ceramic and fiber.

1.Indication position: can be applied in switch of home appliance, control board, plug, lock, electric torch, stairway, fire protection facility, fire alarm, lifesaving tools etc.

2.Building:can be applied in building wall, tiles, inside surface of elevator, bridge, roads, sea ports etc. both decoration and application value has been achieved.

3.Others: arts and crafts, amber, sand crystal, glass, painting works; toys: plastic toys and piece together pictures; clothing: shoes, caps, working uniform, helmet, transfer pictures, printing graph clothing; calendar, fishing tools.

Application Notice

Most of the photoluminescent pigment are less soluble in water and decomposed in acid, so they can not be used in water-base or acid-base media. For these application, pls use our envelope style pigments. Pls contact us for further details.

Mix pigment well before using in terms of its gravity.

Keep pigments in breezy, dry warehouse and make it free from humidity. Pack the rest pigment carefully after one time usage.

Metal material influence the pigment, so prevent pigment from touching metal material.

Reference information of Rare earth long after glow in the dark powder

REE-activated alkaline earth aluminate, silicate and other high-tech self-luminous products. Their outstanding characteristics are: a variety of visible light absorption at 10 to 20 minutes, you can continue to light at night in the dark more than 12 hours, the luminous brightness and duration is 30 to 50 times the traditional ZnS glow materials.

Glow in the dark powders main technical parameters:

1 initial brightness: glow powder under a certain light brightness (1000LUX), instrumentation brightness value between 0 (typically 3 seconds after the light extinguished) moments. General highlighted photoluminescent powder around 20000-25000. Since the initial rapid reduction sad moment, capturing moments error greater impact on the general brightness with one minute to more appropriate time. Highlight luminous powder is generally 3500 (med/m2) above, in the light powders in 2800, Pu Liang powder at about 2300.

2 persistence: over time, the brightness powder falling, respectively, comparing the luminance values at different times, to measure the speed of less luminous sorrow. Generally 10 minutes, 30 minutes, one hour brightness for comparison.

3 Granularity: Granularity is an important parameter photoluminescent powder, the application performance of its glow powder has a great influence, generally with an average particle size and particle size distribution to describe the characteristics of the unit is micron (um), these parameters are passed particle analyzer test out. But in reality, in order to facilitate more with ‘mesh’ (mesh number of single living area) to describe the granularity of the situation, luminous powder is generally based on the production process is divided into -160 mesh, -200 mesh, -250, -300 , -400, -200 to +400 mesh, -160 to +250 mesh and so on. Generally, the same powder quality, the larger the particle size, the better the brightness, the worse the performance; smaller the particle size, the greater the specific surface area, the larger the dispersion

中文

中文