Photoluminescent film

Other key words: glow in the dark film, luminous tape, photoluminescent adhesive vinly

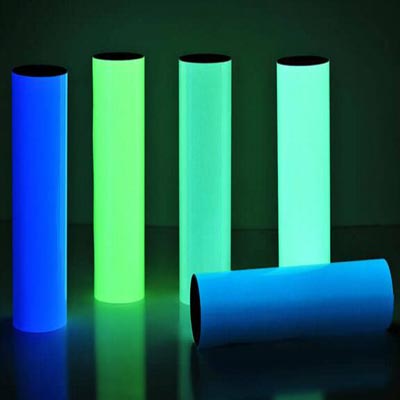

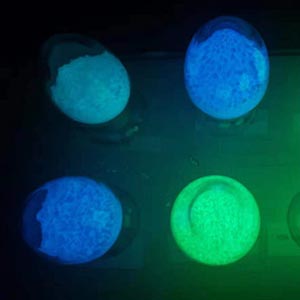

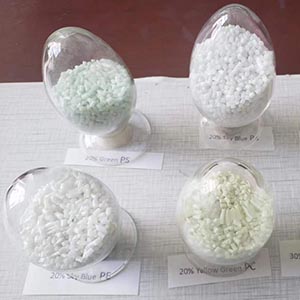

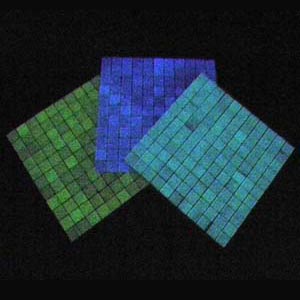

Glow color: yellow green, blue green, sky blue

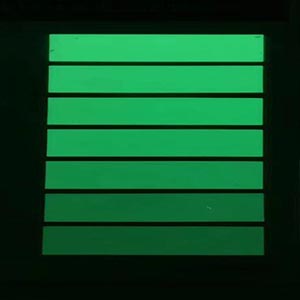

Size: 1*10 meter, 1.24*50 meter each roll or customize

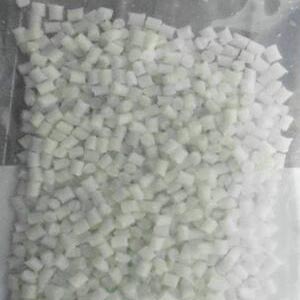

Materials: PVC, PET, PMMA

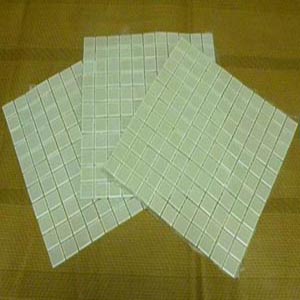

Type: back glue or without adhesive type; glossy or matte surface type.

- Description

- Inquiry

Description

Brief Introduction:

Glow in the dark film are made from photoluminescent materials. Storing light firstly then glowing in the darkness. They can automatically glow in the dark for long time after absorbing various visible light . This process of absorbing-emitting can be repeated forever. They are nontoxic, harmless, free from any radioactive substance, easy-applied and with climate-resistant With better chemically stability.

Features:

1, STORING a short time, a large light-receiving area, high luminous intensity, long afterglow time;

2, non-toxic, no radiation, no pollution;

3, there are self-adhesive backing material, free paste;

4, processing easy, wide carving, cutting, printing, using surface;

5, environmental adaptability, excellent heat resistance, cold resistance;

6, the surface of the light uniformity, good finish.

Application Scope:

Free to make free stickers, decorative painting, tag, card, calendar, car stickers, fire marked, public labeling, zodiac, auspicious patterns and other personalized luminous products, is emerging advertising, decoration materials; easily processed because of green energy, has gradually into the decoration industry, such as personalized children’s room, living room decor, room night barriers tips and more.

Color: mainly to yellowish green, other colors can be customized.

Life: indoor eight years, outdoor five years.

Packaging and storage:

1, Packing: Carton

2, Storage: should be stored in ventilated, dry coffers

Reference Information

Photoluminescent film using methods and precautions

1.should be on a flat surface construction, construction temperature should be 10 — 40 C.

2.Can be cut into various shapes photoluminescent film, directly affixed to somewhere (such as telephone, switches, etc.) play a decorative, indicating the role.

3.The light-emitting surface of the film screen printing patterns, text and other methods, the formation underlay light.

4.Affixed to the surface should be cleaned at the first surface, the surface can not have oil, dust, etc.

5.The light-emitting thermal expansion and contraction of the film has a certain luminous film after slicing can not be left unattended and should put the folder or put heavy pressure, prevent deformation and curling.

6.Adhesive glow tape to the backing paper and the light emitting humidity influenced by thesize of the light emitting film to be sliced is placed at a relative humidity of 40 to 60% under the process environment, to prevent curl.

7.Using the back of the luminous film release paper is removed, the film will be some pressure luminous flat surface affixed to a good deal, pay attention to corners paste Hao.

8. The same type of glow in the dark film in order to ensure there will be some different luminescent color brightness lot.

9. Four color film, there is fading in the sunlight phenomenon, should pay attention to, especially not for outdoor use.

10. Light film roll may be longer than 10M connector.

中文

中文