Photochromic pigment

The Photochromic pigment is a photochromic powder material made by wrapping the reverse photochromic dye in the microcapsule. The product improves the solubility of OP oil, allowing it to be uniformly dispersed in water-based systems. MC is white in an indoor light source environment and becomes the color of a dye under ultraviolet or sunlight. It can be added directly to the appropriate application for use. The average particle size of the photosensitive microcapsule powder is 3-10μm, which is a microcapsule powder containing 2% to 5% of the photochromic powder, and the moisture content is ≦3%. Suitable for water-based, oil-based ink, paint and plastic injection, extrusion Photosensitive microcapsule powder is a pigment, characterized by bright color, high temperature resistance and solvent resistance, which can be used in plastic injection, oily ink and paint.

- Description

- Inquiry

Description

First, the principle of color change:

Photochromic material that absorbs sunlight/ultraviolet light and absorbs sunlight/ultraviolet energy to produce color changes.

When the sun/UV is lost, it returns to its original color.

Use sunlight (UV light) to control color changes.

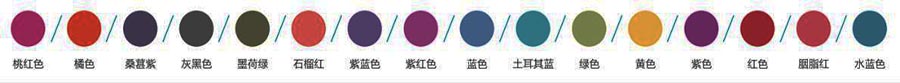

Second, the basic color:

Peach, red, orange, yellow, green, blue, purple, purple blue, purple red, gray and other 16 kinds

Third, the law of discoloration:

3.1: Colorless and colored.

3.2: Colored and colored (adding other fluorescent toners, toners, etc., can be colored and colored).

Fourth, the form and application of photosensitive color-changing materials:

4.1: Photosensitive MC microcapsule powder: suitable for oily ink coating, water-based ink coating, plastic injection, extrusion.

Fifth, the recommended ratio of photosensitive color-changing materials:

5.2: Photosensitive MC microcapsule powder for oily inks and coatings 3%-30% W/W (20%)

5.3: Photosensitive MC microcapsule powder for aqueous inks and coatings 3%-30% W/W (20%)

5.4: Photosensitive MC microcapsule powder for plastic injection and extrusion 0.2%-5% W/W (0.5%)

Sixth, the use of photosensitive color materials:

6.1: Coating: Suitable for surface coating of all kinds of plastic products, including ABS, PE, PP, PS, PVC, PVA and other plastic materials.

6.2: Ink: Suitable for printing on various materials, such as fabric, paper, synthetic film, glass, metal, etc.

6.3: Plastic: Suitable for injection and extrusion of various plastic materials (including PE, PP, ABS, PS, PVC, PU,

TPU, TPR, EVA and other plastic materials).

Seven, note:

7.1: The ink substrate is suitable for pH 7-9. The plastic substrate is more suitable for MI value greater than 25. The larger the MI value, the better the color change effect.

7.2: Light fatigue of photochromic materials caused by excessive exposure to UV light, acids, free radicals (single-state oxygen atoms) and humidity,

It is generally recommended to add UV absorbers and antioxidants to increase the resistance to light fatigue.

7.3: Additives used in photochromic materials such as HALS, antioxidants, thermal stabilizers, UV absorbers and inhibitors can improve light fatigue resistance,

However, the combination and selection of additives depends on the medium used, and the wrong combination formula will accelerate the light fatigue.

7.4: If there is agglomeration in the photosensitive water emulsion, it can be stirred and heated in a water bath to be redispersed before use.

7.5: Photochromic materials do not contain substances harmful to human body, and meet the safety toy and food packaging specifications.

Eight, storage methods:

Store in a cool, dry place, away from direct sunlight.

Remarks: 1. Photosensitive series products, except for photographic dyes, are all pigments, which will produce different levels of shielding effect.

When applying optically variable materials, please confirm their sunshine resistance and meet customer needs.

中文

中文