Thermochromic pigment

Types of thermochromic pigments:

Thermal achromatic type: colored state at low temperature, when the temperature rises to the set value, the pigment changes from colored to colorless. Its color change temperature can be set in the range of -20 ~ 70 ° C according to user needs: The R series color-changing pigments have the most varieties, complete chromatography, and are the most commonly used color-changing pigments.

Hot hair color type: its color ~ temperature characteristics are opposite to the R series. It is colorless at low temperature, and the pigment changes from colorless to colored when the temperature rises to the set value. Its color temperature range is: 60 ~ 65℃.

- Description

- Inquiry

Description

The color-changing principle and structure of reversible thermochromic pigments:

Thermochromic pigments are microcapsules that repeatedly change color as the temperature rises or falls.

Reversible thermochromic powder is prepared by electron transfer organic compound system. Electron transfer organic compounds are a kind of organic hair color system with special chemical structure. At a specific temperature, the molecular structure of the organic matter changes due to electron transfer, thus achieving color transformation. This color-changing substance is not only bright in color, but also can achieve color change from the state of “color === colorless” and “colorless === colored”, which is not possessed by heavy metal complex salt complexes and liquid crystal reversible temperature-sensitive color-changing substances.

Microencapsulated reversible thermochromic substance is called reversible thermochromic pigment (commonly known as: thermosensitive pigment, thermochromic powder). The particles of this pigment are spherical, with an average diameter of 2 to 7 microns (one micron is one thousandth of a millimeter). The inside is a color-changing substance, and the outside is a transparent shell about 0.2 to 0.5 microns thick that can neither dissolve nor melt, which protects the color-changing substance from erosion by other chemicals. Therefore, it is very important to avoid damaging this shell in use.

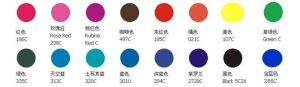

Basic colors of thermochromic pigments:

At present, the reversible thermochromic pigment supplied by the company has the following 16 colors in the color development state:

Colour change temperature of thermochromic pigment

1, temperature change temperature

In fact, the color change temperature of the color-sensitive pigment is not a temperature point, but a temperature interval, that is, the temperature range from the beginning to the end of the color change (T0 ~ T1). The width of this temperature range is generally 4~6 ° C, and some varieties with higher discoloration accuracy (narrow range varieties, represented by “N”) have a narrower discoloration temperature range, only 2~3 ° C.

In general, we define the temperature T1 corresponding to the basic completion of discoloration during the constant velocity heating process as the discoloration temperature of the thermochromic pigment.

2. Number of temperature-sensitive discoloration cycles:

Take a little of the color-changing pigment to be measured, mix it with 504 epoxy glue, and scrape the sample on white paper (thickness 0.05-0.08 mm) at room temperature above 20℃ for one day. Cut 10 x 30 mm paper pattern. Take two 600mL beakers and fill them with water. The water temperature is 5 ~ 20℃ above the upper limit of the sample discoloration temperature range (T1) and no less than 5℃ below the lower limit (T0) (for RF-65 series inks, the water temperature is T0=35℃, T1=70℃), and the water temperature is maintained. The sample is immersed in two beakers in turn, and the time to complete each cycle is 3 to 4 seconds. Observe the color change and record the number of reversible color change cycles (usually, the number of color change cycles of the thermal achromatic series is greater than 4000-8000 times).

Application of thermochromic powder

1.The reversible temperature-sensitive color-changing substance microencapsulated is called reversible temperature-sensitive color-changing pigment (commonly known as temperature-sensitive pigment, temperature-sensitive powder or temperature-sensitive powder).

2.This product can be used for injection and extrusion molding of polypropylene (PP), PE, PS, PU, TPU, TPR, EVA, soft polyvinyl chloride (s-pvc), ABS, silicone and other transparent or translucent plastics.

3, for injection, extrusion processing or casting, molding, molding, curing, the amount of discoloration pigment is 0.2-5% of the amount of plastic, usually 0.5-2%; Discoloration pigment and plastic particles to fully mix uniform, mixing can use a small amount of white oil.

4.Temperature: Processing temperature should be controlled under 220 ℃, the highest do not exceed 250 ℃, and try to reduce the time for heating the material (high temperature and long heat will damage the paint color performance).

Precautions for use

1.When coloring pigments are used in injection and extrusion, other fillers or common pigments (such as titanium dioxide, calcium carbonate, barium sulfate, carbon black, etc.) should not be used at the same time in plastics, otherwise the color changing effect will be shielded.

2.When the color-changing pigment is used in casting, molding and curing, the color-changing pigment should be added into unsaturated polyester, plexiglass or nylon monomer and stirred and dispersed evenly, and then the initiator or curing agent should be added to initiate polymerization or crosslinking reaction. Because the viscosity of the system increases sharply after prepolymerization, the addition of discoloration pigment will make a large number of pigment particles wrapped together, which is difficult to disperse evenly. In addition, a large number of bubbles will remain in the system during the stirring operation.

3.Careful selection of cross-linking agent or curing agent: in the cross-linking curing process of epoxy resin and unsaturated polyester resin, strong shrinkage stress will sometimes occur in the interior, which will lead to the rupture of the shell of the color-changing pigment microcapsule, and other chemicals will enter the interior of the pigment to make it lose its color-changing performance. This often occurs when epoxy is thicker than 0.2 mm and polyamine hardeners are used.

4, can not use the mixer, kneading machine, high-speed disperser, twin-screw extruder and other high shear equipment for plastic particles and pigment pre-mixing. These devices can seriously damage the protective layer on the surface of the discoloration pigment, making it lose its discoloration performance. In addition, the color masterbatch should be prepared to prevent the pigment from repeated extrusion granulation.

5, in the formulation of PVC resin should avoid the use of phosphorus stabilizer and plasticizer, otherwise it will make discoloration injection products in the state of achromatic produce serious residual color.

Storage method:

Reversible temperature-sensitive pigment itself is an unstable system (stability is difficult to change), so its light resistance, heat resistance, aging resistance and other properties are far less than ordinary pigments, should be paid attention to in use.

Store in a dry and cool place sealed away from direct sunlight.

中文

中文